Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

Brazil's University of São

Paulo (USP) is using TMS SmartShakers in research on Flow-Induced Vibration (FIV). The research team, headed by the Department of Mechanical Engineering's Professors

Leopoldo de Oliveira and Paulo Varoto, teamed up with Professor Gherhardt Ribatski from the Thermofluids group, to design experiments using tube bundles to represent a nuclear plant's steam generator.

Brazil's University of São

Paulo (USP) is using TMS SmartShakers in research on Flow-Induced Vibration (FIV). The research team, headed by the Department of Mechanical Engineering's Professors

Leopoldo de Oliveira and Paulo Varoto, teamed up with Professor Gherhardt Ribatski from the Thermofluids group, to design experiments using tube bundles to represent a nuclear plant's steam generator.

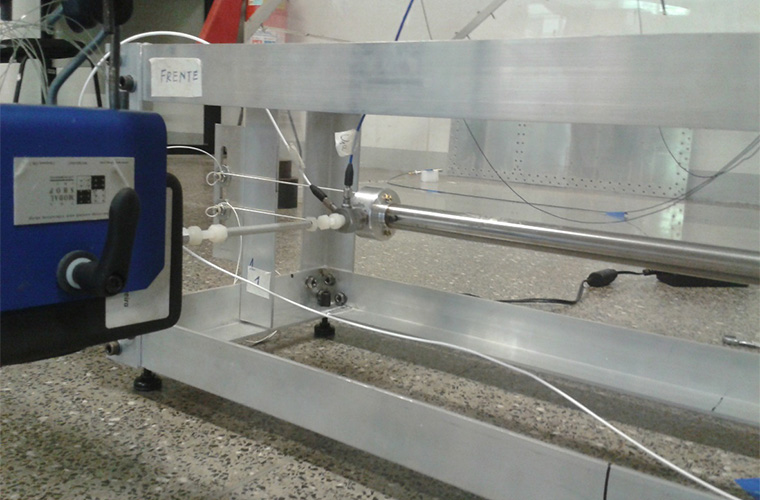

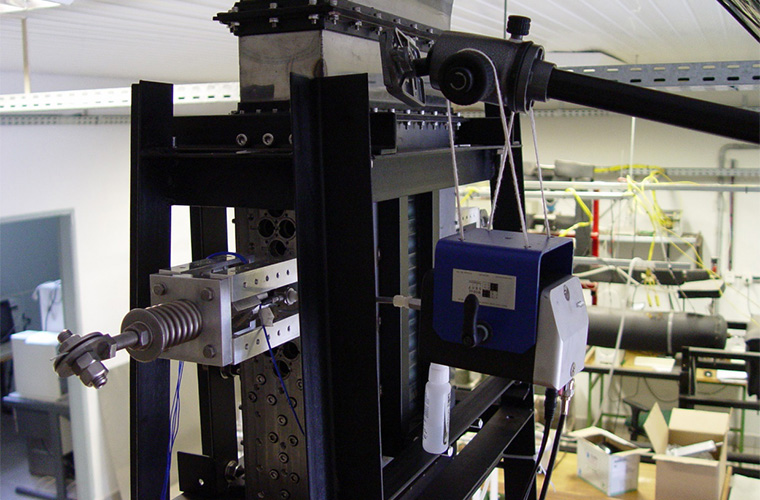

Shaker excitation is used to tune the wires that provide the suspension stiffness for the tube, to be mounted on the tube bundle

When critical failures in nuclear power plant equipment began to occur in the 1960s, engineers realized that a lack of knowledge in Flow-Induced Vibration (FIV) in nuclear power plant heat exchangers could be a factor. Since then, several experiments have been performed to understand the causes of these vibrations, both in single-phase and multiphase flow cases.

The São Paulo research

team's experimental apparatus consisted of a dynamic subsystem constructed to perform experiments addressing the mode shapes and resonant frequency range of tube bundles typical for heat exchanger tubes. The apparatus consisted of an aluminum frame

and tensioned guitar wires with accelerometers for measurement and a Siemens LMS SCADAS Mobile system running Test.Lab data acquisition software.

The São Paulo research

team's experimental apparatus consisted of a dynamic subsystem constructed to perform experiments addressing the mode shapes and resonant frequency range of tube bundles typical for heat exchanger tubes. The apparatus consisted of an aluminum frame

and tensioned guitar wires with accelerometers for measurement and a Siemens LMS SCADAS Mobile system running Test.Lab data acquisition software.

Shaker excitation allows for tuning the suspension stiffness and also to acquire FRFs under various flow conditions

This subsystem was excited with a Model K2007E01 electrodynamic shaker from The Modal Shop, Inc. Force and acceleration were measured with an impedance head, Model 288D01 from PCB Piezotronics, installed at the force application point. The experimental apparatus was used in air, water and multiphase environmental test cases.

During the experiments, it was possible to observe that for Frequency Response Functions (FRFs) measured in the air-water environment, the higher the air flow, the worse the FRF quality. The FRFs' bad quality is related with the difficulty of measuring distributed force exerted by the bubbles over the tube. Despite this, it was seen that the FRFs' overall level always appeared below the pure water environment FRFs, meaning that great behavior changes are not expected under multiphase environmental cases.

Click here to read the full technical paper.