Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

The Mini SmartShaker with Integrated Power Amplifier is an electrodynamic exciter designed for general purpose vibration testing of small components and sub-assemblies up to 11 kHz. It can also be used as excitation for modal testing of small structures.

The SmartShaker was developed because people needed a simple and easy-to-use vibration tool for their studies. No matter if you are testing a device, if you are doing an experiment or a research project, the SmartShaker provides a combination standard general purpose vibration shaker and a power amplifier all in one combined piece.

It allows easy connection of the shaker to a signal source or a vibration signal for the use in experiments. An object can be mounted or attached to the shaker: smaller electronics, a Smart Phone, or a little structure. The shaker can also be connected to a structure in the experiment through one of the stingers provided along with the shaker.

It’s a very compact, easy-to-use, integrated tool to provide controlled vibration excitation during a testing experiment or in a lab setup.

The SmartShaker is a very compact tool. The amplifier and the shaker are integrated into one piece, making it easy to use on a mechanical engineering laboratory workbench or in a civil engineering laboratory.

One SmartShaker can be shared by a group of students and can be set up in a lab environment to be driven using a bench-top function generator. Vibration can be monitored using an accelerometer and checking the vibration signals with a signal scope or an analyzer.

It can be easily integrated with the standalone classical laboratory equipment found in most universities and engineering schools. Plus, the fact that SmartShaker is really small, you can easily reproduce real world experiments.

Let’s say you’re trying to test a new material or a new design for a car or an airplane. You can do a small scale experiment in a laboratory setup trying to reproduce real world environmental stress and environmental excitation that you would see in the airplanes or in the cars. You can reproduce the same signals by just using a small compact vibration exciter like the SmartShaker.

The beauty of it is that you have control over the vibration excitation you are putting to your experiment, so you can test different types of inputs and see how the outputs look. In this way, you can model and to validate the behavior of structures, test new theories and new materials, new design approaches and so on. And that can all be done using a very compact, easy-to-operate tool in a school laboratory or research project.

Yes they are. You can always contact the Modal Shop or our local distributor and ask for the availability of a SmartShaker. Also, if you need it for an extended time you can rent a unit from the Modal Shop. Please visit the Rental Page to see the full range of products available. You may contact us by phone, +1 513 351 9919 or by email, sales@modalshop.com, and we will find the best way to get you a SmartShaker.

The SmartShaker is used in the following areas:

Here are some quick steps to get the SmartShaker up and running:

The shaker body structure and trunnion assembly are designed to allow a variety of operating positions. The shaker is typically used in the vertical orientations and can be rotated up to 90° for horizontal applications. The shaker can also be suspended from it's trunnion to accomodate exciting a test article from different angles. The excitation is delivered with a variety of 10-32 nylon stingers which provide electrical isolation from and flexible attachments to test articles.

The SmartShaker can be used as a vibration table in a control system. Test articles can be mounted to the shaker's mounting platform. Objects such as small electronic items, a Smartphone, or a small biomedical device can be tested using the shaker driven by an analyzer or a vibration controller.

The SmartShaker has a BNC input that allows it to be easily driven from a signal source.

Typically a sensor can be used to monitor the vibration of the shaker and also the vibration on the test article. Those two vibration shaker measurements can be fed back to the analyzer or to the control system for further analysis.

*App Required

**Software Required

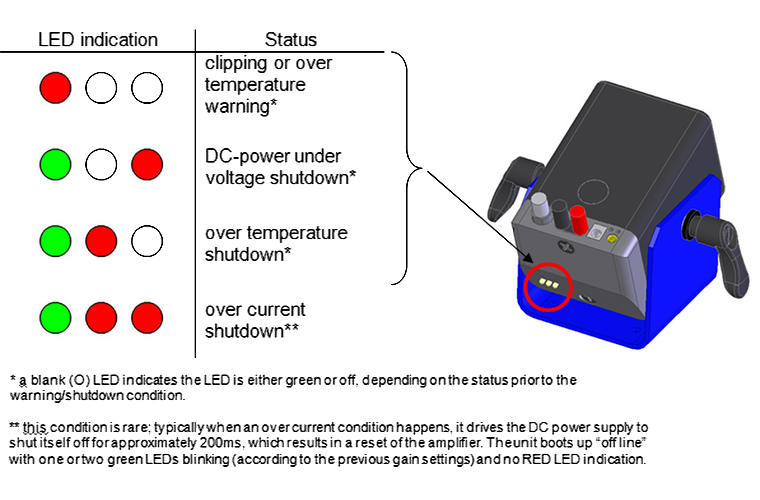

Yes. Also, the LED will turn red as a shutdown indication.

The gain knob was intentionally designed to be difficult to access. Typically the gain is set once and does not change. Shaker level is controlled via input signal level coming from an analyzer, vibration controller or function generator.

You can find videos and training information about how to use the SmartShaker here.

Visit The Modal Shop's YouTube page where you can access all the training videos on how to use the SmartShaker.

The K2004E01 and K2007E01 are specified up to 9 kHz and 11 kHz respectively. This can be seen as a conservative specification considering the SmartShaker has a primary resonance typically around 10 kHz. Based on ISO 5344, the relevant shaker ISO standard, shakers are typically useable to approximately 1.5 times the primary resonant frequency. Accordingly, these shakers are useable to approximately 15 kHz. The shakers will certainly work to higher frequencies, but at some point force "drop-outs" will be seen, where the shaker has near zero output regardless of input energy. Since these resonance (and anti-resonances) shift depending upon payload, higher mass load will tend to decrease this useable frequency range. With that said, reaching 15 kHz with a lighter payload is attainable.

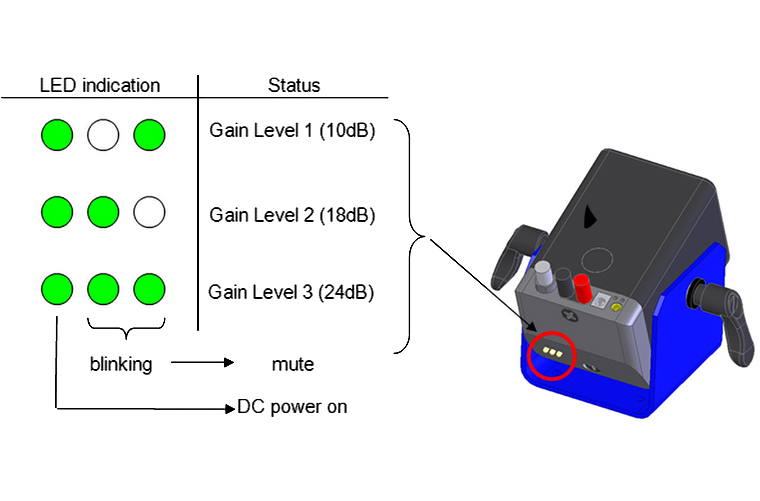

The minimum value is zero volts. The maximum recommended input voltage is determined by the gain setting. There are three discrete gain levels available. Maximum signal input for full unclipped output will vary between 0.25 – 1 VRMS dependent on the gain. After that, clipping starts to occur. The absolute maximum input voltage is approximately 1.9 VRMS.

The payload refers to the total weight due to the mass of the test specimen plus any type of test fixture used. A 2 lbs (0.91 kg) payload is a general guideline. For vertical operation, the shaker stroke capability is 0.5in (12.7mm) pk-pk or ± 0.25in (6.35mm). Any load you put on the shaker will offset the armature down. A static deflection of the armature is permissible as long as the sum of the required test displacement and the static deflection is less than 0.25in (6.35mm) from the neutral position.

*Country compatible power plug supplied

The foam is to protect the inside of the shaker, like a dust filter, and at the same time to let air flow through for natural cooling.

The trunnion base is the blue base around the shaker. It allows rotation of the shaker to the right angle orientation; it also allows the shaker to be suspended or the attachment of the shaker to a table or mounting surface for testing.

The EasyTurn handles are the handles used to tighten or loosen the trunnion to allow rotation of the shaker and to secure the right angle/alignment position.

The SmartShaker comes with a set of three nylon stingers, model number 2110G06, and replacement stingers can be ordered directly through The Modal Shop website by emailing sales@modalshop.com. You can also reach us toll free at 800.860.4867 or +1 513.351.9919.

The SmartShaker is designed to provide trouble-free service for long periods of time when operated with the performance limits and in an environment which is free of excessive dust, metallic particles and other potentially harmful materials. The only maintenance that should be performed on a routine basis, outside of replacement of worn or damaged components, is the cleaning of the air filter. Inspection of the shaker moving element (flextures, armature and wiring) can be performed if operational problems are suspected.

The SmartShaker was designed with reliability and toughness in mind. The internal elements of the shaker include carbon flexure suspension system. When mounting objects on top of the shaker table, the shaker will support the torque applied during the mounting efforts. The shaker’s integrated amplifier indicates distortion and also includes over current protection.

The SmartShaker will withstand a reasonable level of abuse. It is one of the reasons this product is very popular.

But in the rare event that the shaker breaks, which is possible, contact The Modal Shop or your local distributor and describe what happened. Ask for a return authorization. The shaker will be evaluated and you will be provided with a repair estimate.